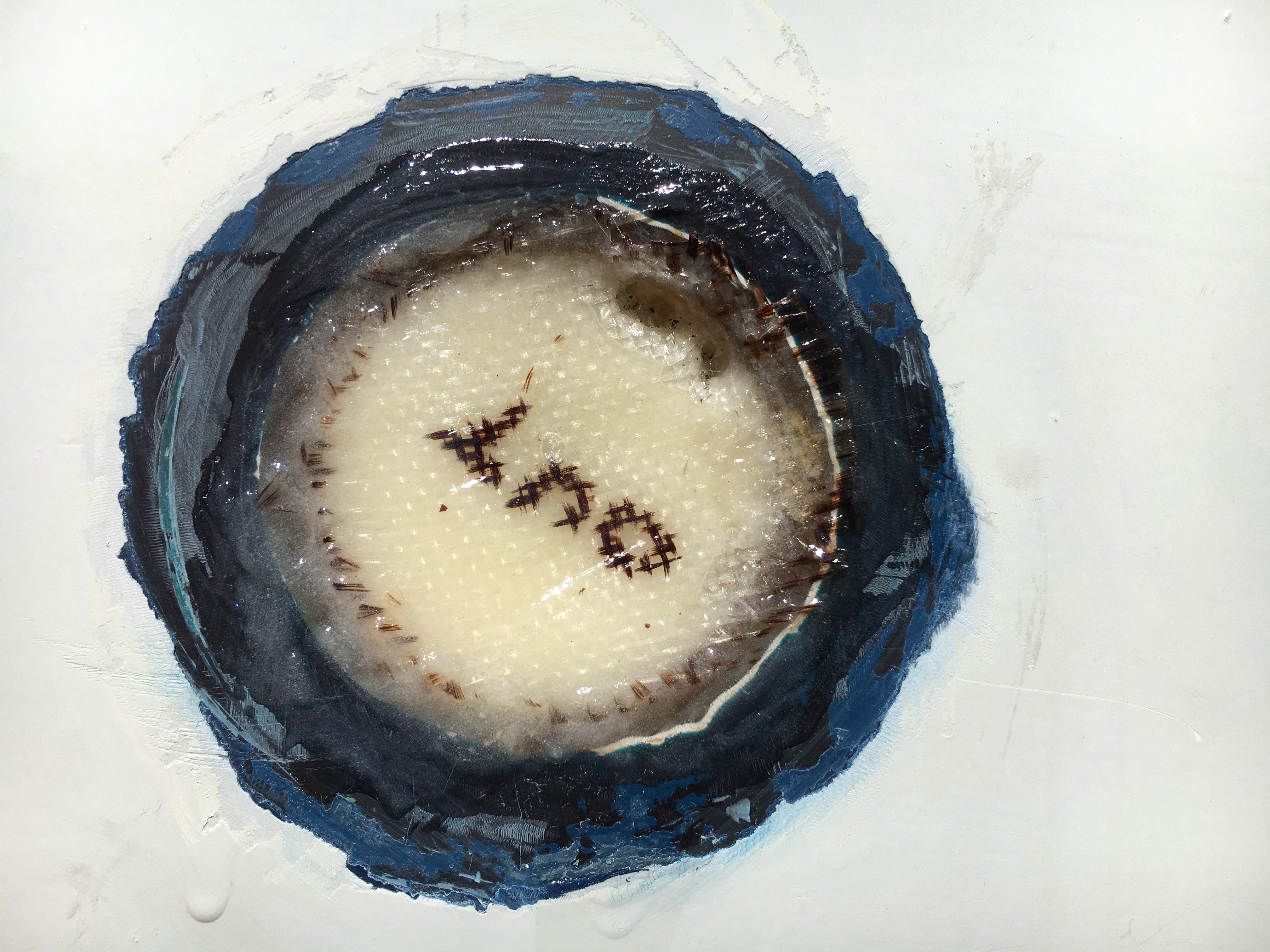

- Hull thickness at the manual bilge pump opening is 9/16"

- Removed wooden backing plate.

- Removed thick wad of silicone used to "glue" backing plate to the hull. Was able to peel most of the silicone off in a few large pieces. Silicone adheres to itself far better than to other surfaces.

- Using the multitool, chamfered the hole significantly inside the boat reducing the hull thickness to about 1/8".

- Using the multitool, chamfered the hole very gently outside the boat, about 3/16" wide.

- Verified that all silicone was removed using water.

- Cleaned the surfaces, outside, in the hole, and inside with acetone.

- Cut 6oz fiberglass cloth to fit the outside hole closely, and four additional pieces to cover the inside.

- Secured a stiff cover over the hole from the outside.

- Filled the remaining thickness of the hull penetration with a thick mush of 105 epoxy and 206 collodial silica.

- Wetted out by submerging in epoxy the smallest piece of 6oz cloth and placed it over the hole.

- Added the second piece dry, allowing it to draw excess epoxy from the first piece, but ensure it was completed wetted out by adding epoxy to dry areas only.

- Repeated the same method with the last two pieces of 6oz cloth.

-

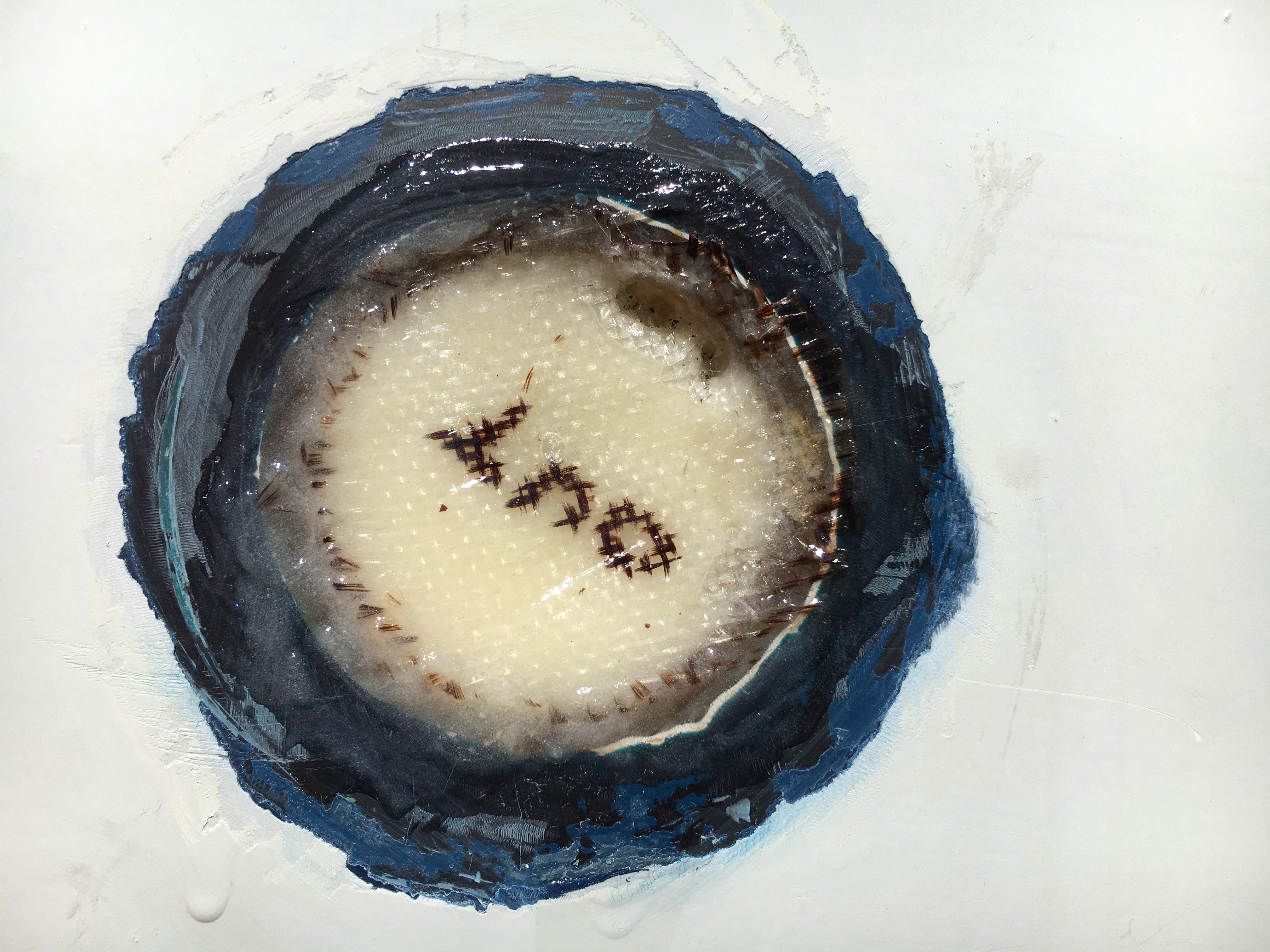

- On the foredeck and coachroof, completed filling the holes for the U-bolt and anchor chocks that lacked some epoxy, after washing the existing epoxy fill and cleaning with acetone. The first fill resulted in significant dimples; some of the epoxy must have wicked into the core material or between the core and skins. No epoxy drips into the cabin; the epoxy did not go there.

![]()