- Cleaned Magna rail mount grill by drilling out pop rivets locking the grill to the body of the unit. Scrubbed all surfaces. Cleaned the cooking surface by placing it inside the oven as the oven performed a self-cleaning cycle.

-

- Sanded the patched area of the hull closed the manual bilge pump thruhull hole.

- Filled patch to bring the closure slightly above the level of the rest of the hull.

-

- Decided upon the location of the replacement manual bilge pump thruhull hole and drilled pilot hole.

- Cut out 4" diameter backing plate for manual bilge pump thruhull.

- Sanded area inside the aft lazarette where the 4" diameter backing plate for manual bilge pump thruhull will be placed.

- Fiberglassed 4" diameter backing plate for manual bilge pump thruhull will be placed using a very thick epoxy and collodial silica mixture. The wooden dowel in the photos was used to make sure the backing plated was centered over the portion of the hull where the hole will be drilled for the manual bilge pump thruhull.

-

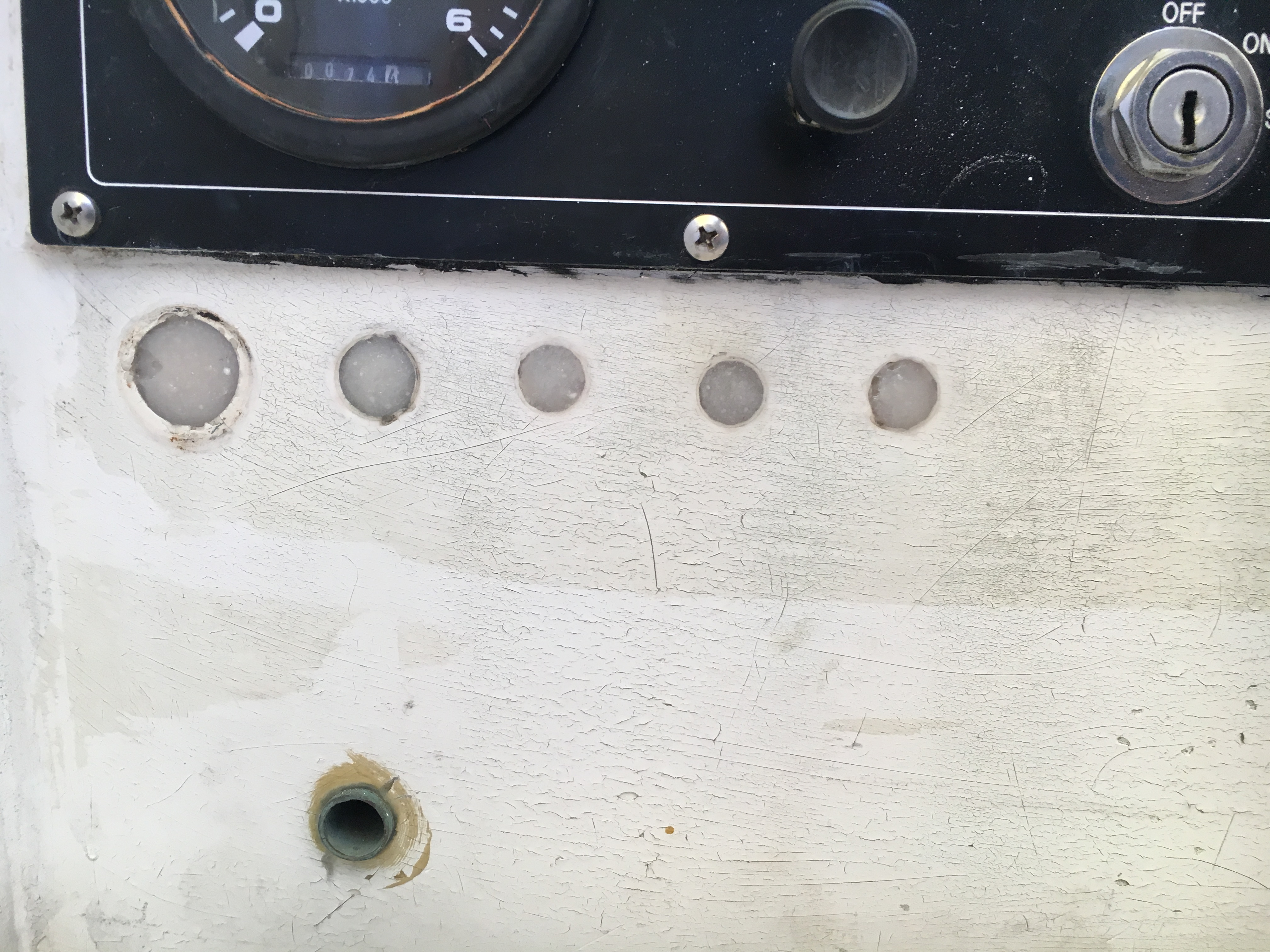

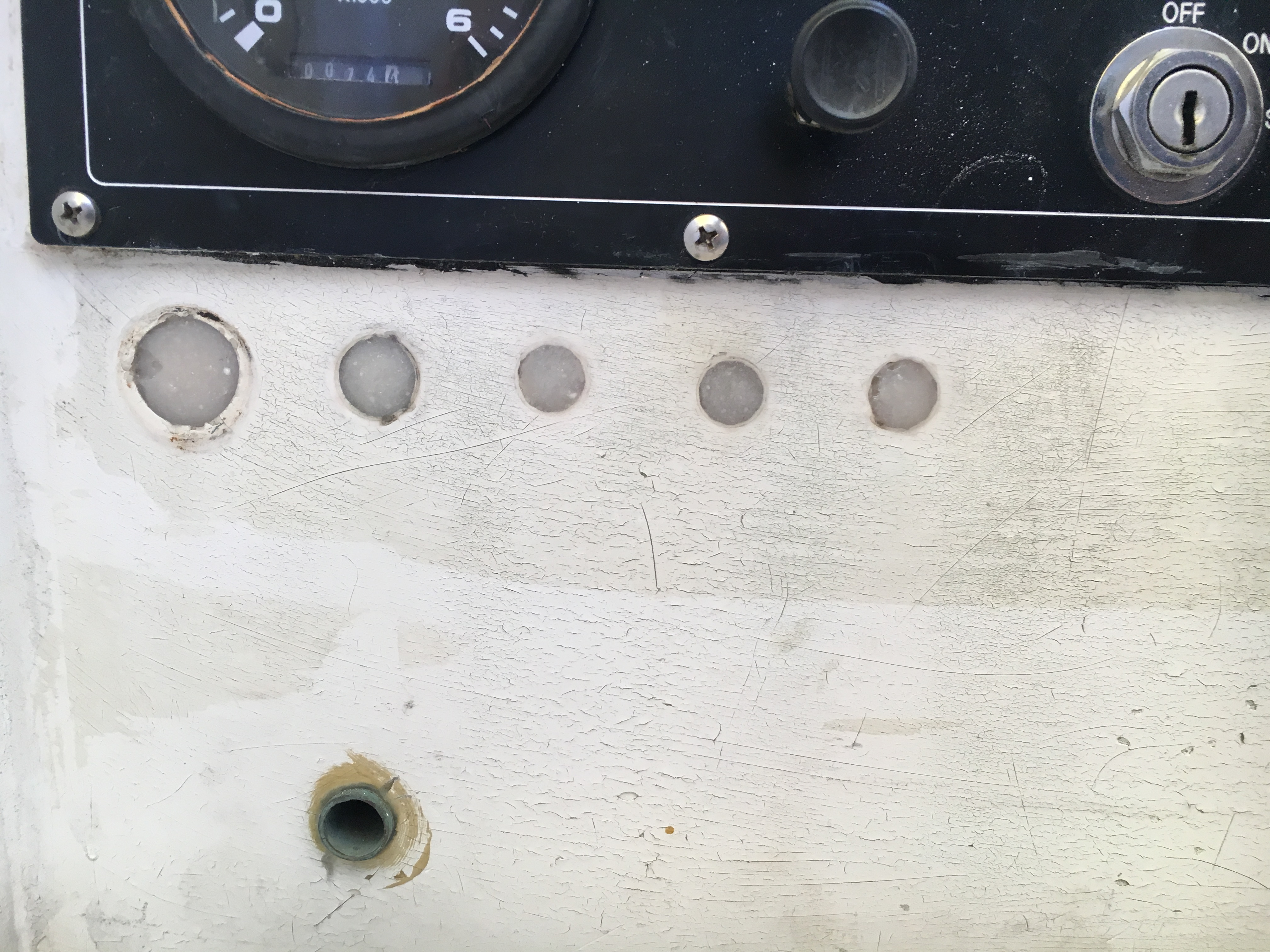

- Removed unused pivoting arm holders from starboard cockpit bulkhead.

- Removed four unused switches and one keyed ignition switch from the cockpit wall below the existing engine instrument panel.

- Removed louvered cover over a hole in the cockpit wall.

- Removed unused winch handle holder from cockpit walls, starboard aft corner, aft, and port aft corner.

- Removed several useless bolts from the cockpit walls.

-

- Chamfered 36 holes, leaving aside the largest diameter holes due to having a chamfer bit of 3/4" diameter.

- Filled all 39 holes with a very thick epoxy and collodial silica mixture.

-

- Applied third coat of paint to lower aft shroud knees.