- Emptied aft lazarette.

- Vacuumed aft lazarette.

- Installed Zerk fitting on both Groco valves in aft lazarette.

- Reversed handle on port side Groco value in aft lazarette.

- Emptied fuel tank.

- Rinsed fuel tank with a quantity of new diesel.

- Added three gallons of new diesel to the tank. Forgot to add the Biobor JF Diesel

and Star Tron SEF Diesel

to the fuel before pouring the fuel into the tank. Will have to do so when filling the tank -- DONE on 20170928.

- Installed a piece of hose to serve as a chafe guard between the cut plywood and the fuel hoses.

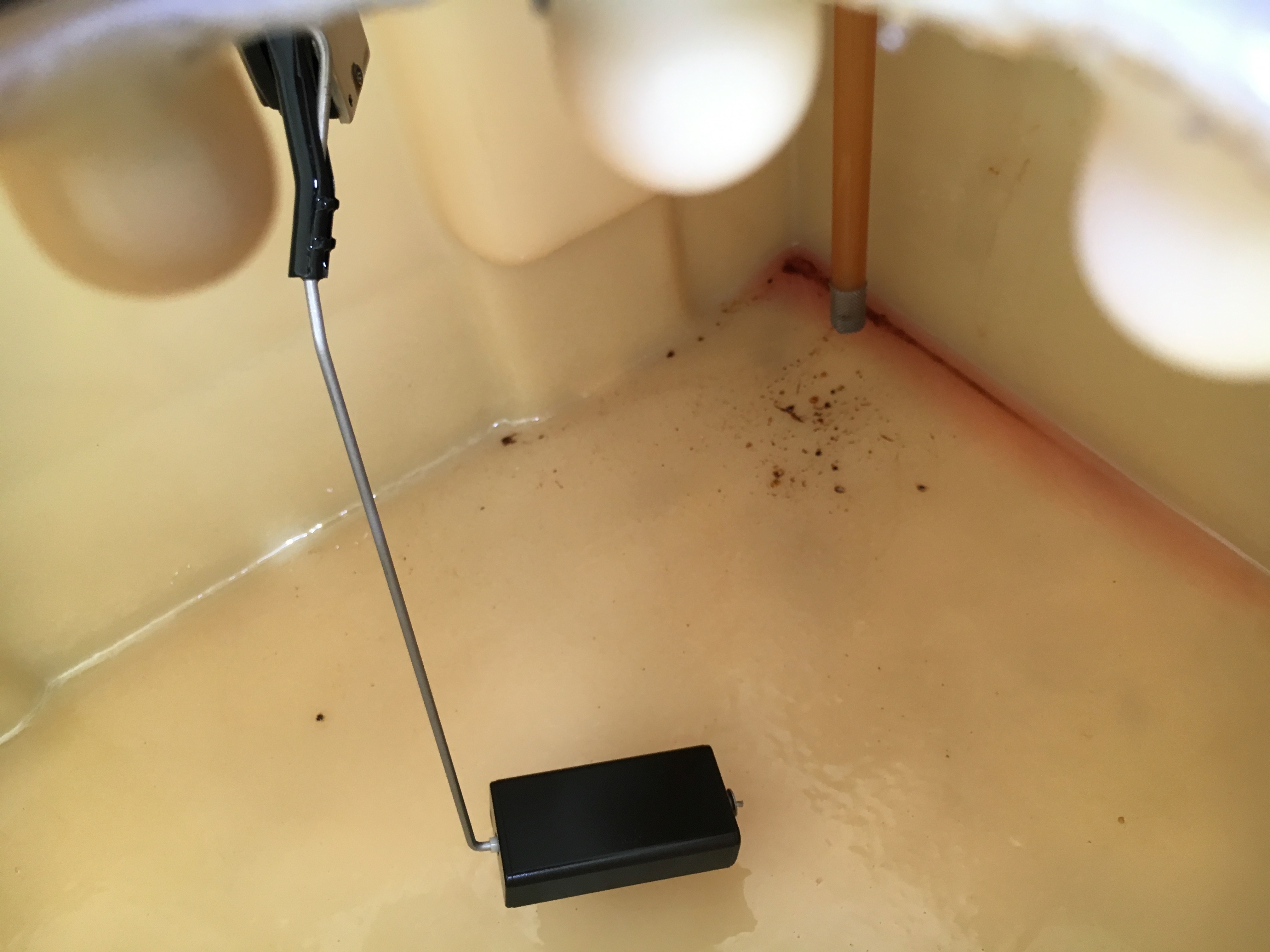

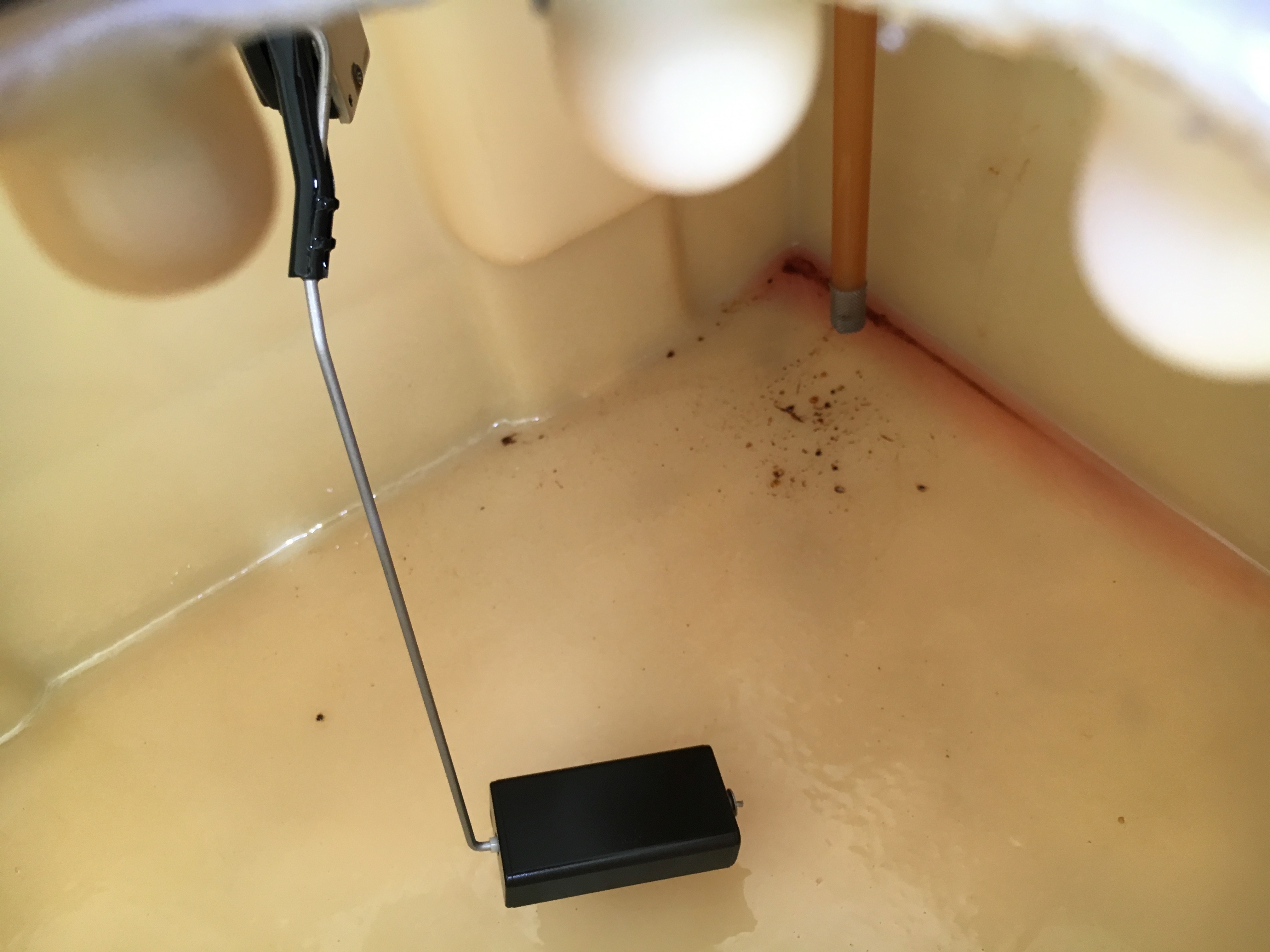

- Installed a single piece of 5/16" ID Barrier Lined A1-15 Fuel Hose #365

from fuel tank to 110A.

- Installed a single piece of 5/16" ID Barrier Lined A1-15 Fuel Hose #365

from the engine to the fuel tank through the same hole as the fuel supply line. Lanolin helps.

- The hose from the Racor 110A to the engine fuel pump is a single piece, as far as I know. Its surrounded with split loom. Not replaced.

- Ran the wires for the stern light through the same hole in the bulkhead between the starboard cockpit locker and the aft lazarette as the diesel fuel lines. The stern light wires run through the same hole in the bulkhead between the starboard cockpit locker and the engine compartment as the diesel return line.

- Some of the other holes in the various bulkhead can now be closed.

- Used the manual priming lever on the fuel pump to bleed the system of air. Required somewhat more than 400 strokes.

- Engine would not start despite running it with the decompression levers activated, and released. Sounded as if it was not getting fuel.

- "Found" another bleed screw at the junction of the braided steel cover line from the on-engine fuel filter and the injection pump. The bleed screw is a 10mm machine bolt with Phillips screw pattern cut into the center. Opened this screw and primed the line using the manual priming lever on the fuel pump.

- Test run the engine at "fast idle", 2000rpm for a minute, and 3000rpm. At 3000rpm, the engine ran for about 40 seconcs(?) then slowed to low idle without stalling. Allowed the engine to run at lower rpm for about half a minute then repeated: 2000rpm for a minute, and 3000rpm for two minutes. No issues.

- Cleaned up from the day's work.

-

- NEED to close the unused openings between the starboard cockpit locker and the engine compartment, and the unused opening between the starboard cockpit locker and the aft lazarette..

- Should I change the run of the engine exhaust? Currently it exits the engine compartment aft wall, port side, into the aft lazarette, rises up tight against the underside of the deck immediately behind the cockpit, passes the starboard side of the aft lazarette, and dives down to the starboard side 1-1/4" valve mounted the to counter. Should it rise up to the underside of the deck and then dive

to the port side 1-1/4" Groco valve?