- Rented a cooling system pressure tester from Pep Boys in Annapolis.

- Cooling system cap on the heat exchanger (radiator cap) appears to be rated for 0.9 bar. Hard to read given the amount of paint on the cap.

- Pressurized cooling system to 20psi (12:01).

- While working on other items, pressure dropped to 14-16psi by 12:09, 11-12psi by 12:32, and 7psi by 12:52. Engine oil appears clean and clear of water at the end.

- Connected 5/8" hose to the small elbow that connects the heat exchanger via an anti-siphon valve to the mixing elbow. Feels clear, no blockage.

- Used a wire to probed the mixing elbow from the small eblow screw fitting. Dirty. Did not find a path to insert as much of the wire as I would want. Need a flexible, smooth end probe.

- Repressurized to 18psi at 12:54 and left boat to work on the mast. Pressure dropped to 10psi by 14:35. Engine oil appears clean and clear of water at the end.

-

- Measured for wiring from the mast to the electrical panel. 24'-6" allows wire to pass along the current (crazy) route via the port cockpit locker.

-

- Backstay's swage, 3/8" wide, just fits into the masthead slot.

- Need a toggle at least 1-1/4" long to connect the forestay to the masthead.

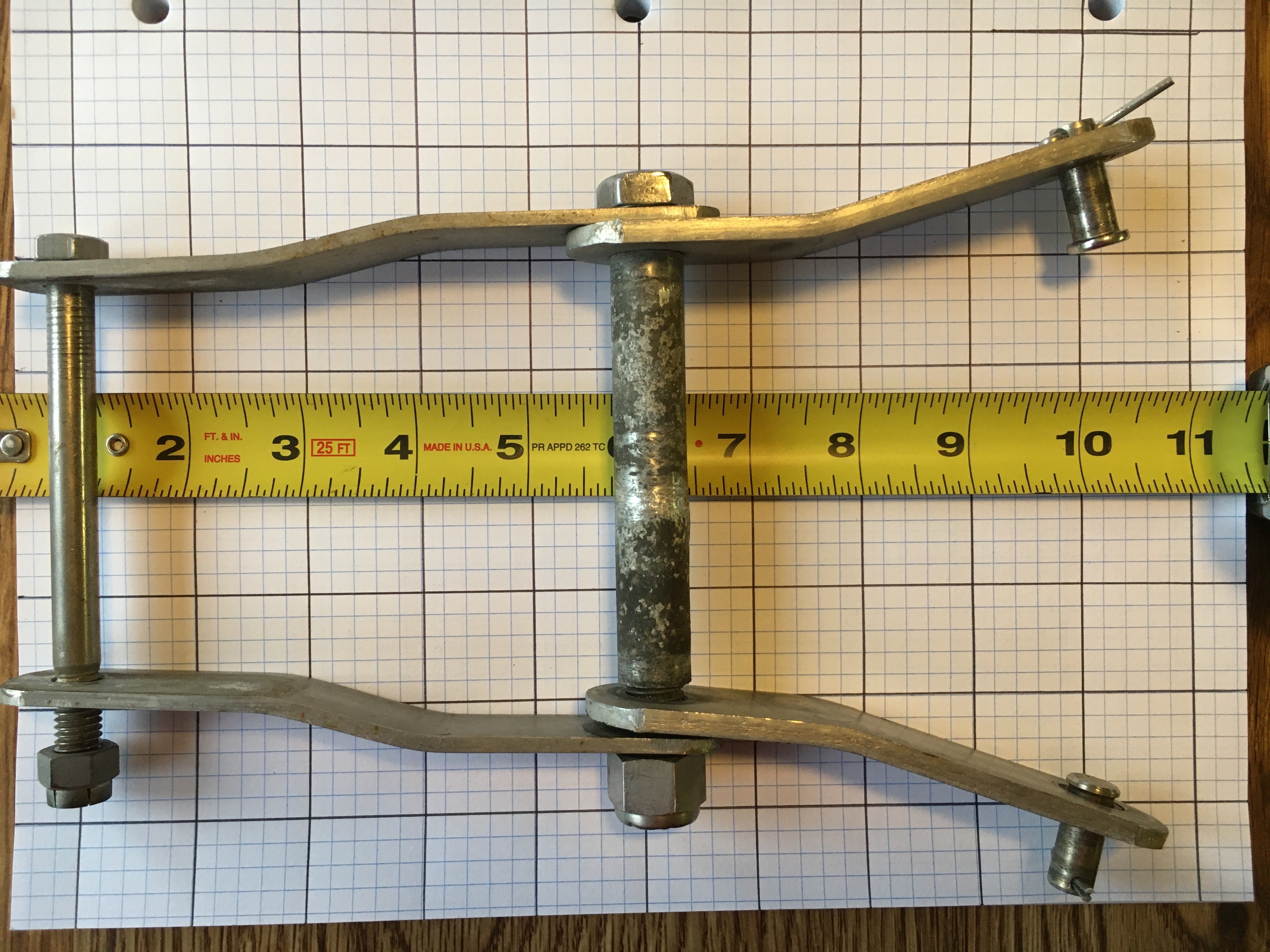

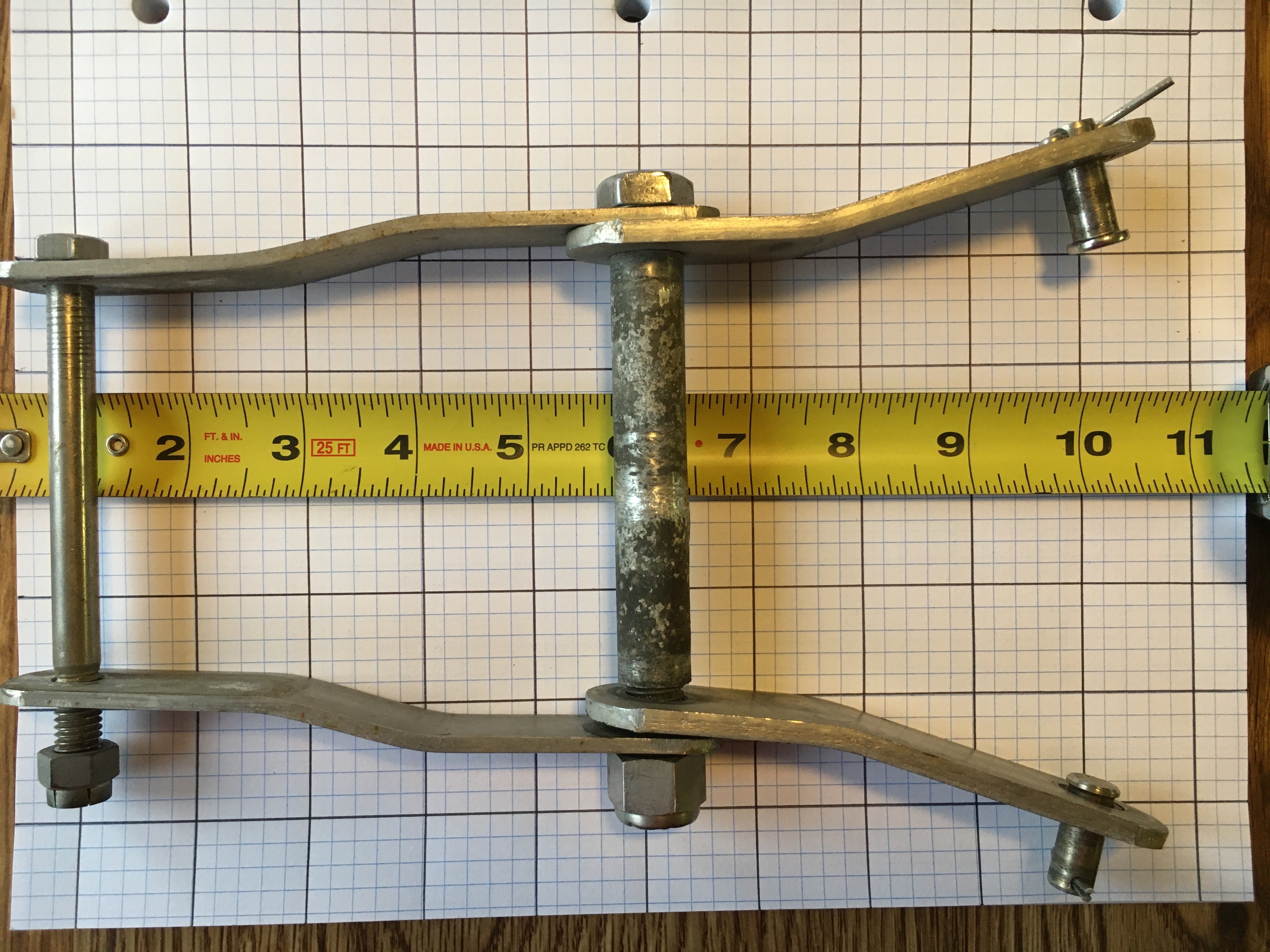

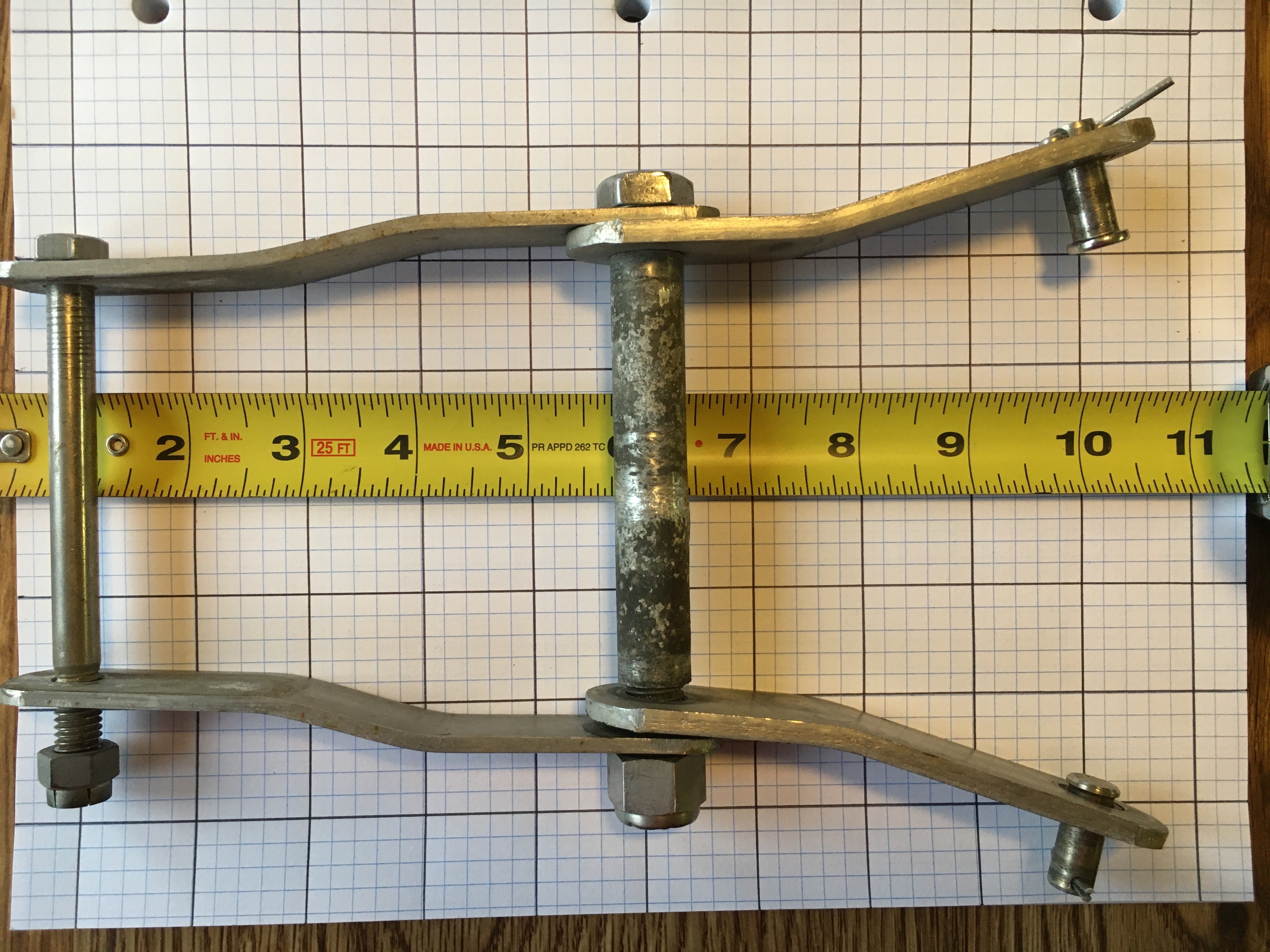

- Rigging screw adjusts from 4-5/8" to 5-7/8" or 1-1/4" total.

- Rigging screw pin center to bottom of furler drum ("T") is 4-7/8".

- Rigging screw pin center to bottom of lower swivel is 9-1/4".

-

- Hammered the main halyard sheave bolt out of the mast using a 1/2" 7 bolt as a drift.

- From the Selden 200 S roller furler, removed the rigging screw.

- Tried to remove the Sta-Lok terminal end as recommended in the manual. Method does not work. Not possible to extert enough force against the parts. The rigging screw is aluminum and liable to damage if enough force was used.

- Cut the 7mm forestay about 3/8" above the terminal.

- Hammered the wire out of the terminal in a vice at home. Several significant blows required to get it break free.

- Main halyard sheave is Tufnol. Original to the boat in 1967. 6-1/4" diameter, 17/32" thick with 0.060" clearance between the sheave and the aluminum side plates (using feeler gauges), 11/32" bore for the 5/8" aluminum sleeve that passes through the mast. Into the sleeve is a steel bolt, seized to the sleeve, that holds the sheave and the cap shroud tangs in place.

-

- Re-measured the rigging before ordering.

- Sent the measurements to Jonathan Adams for review, prior to his ordering from SailingServices