Returning from the most recent

2020 AYC WNR

on 2020-06-24, the engine rpms dropped suddenly and started to stall. Caught it by throwing the engine into idle. Had been having a few fuel problems exhibited as a limit on engine rpm. Had issues previous days as well with not being able to raise the engine to 3,000rpm.

Given the height of the pickup tube above the bottom of the tank, the fuel itself must be contaminated, either in suspension or from material on the bottom that enters temporary suspension due to physical agitation of the tank in the boat.

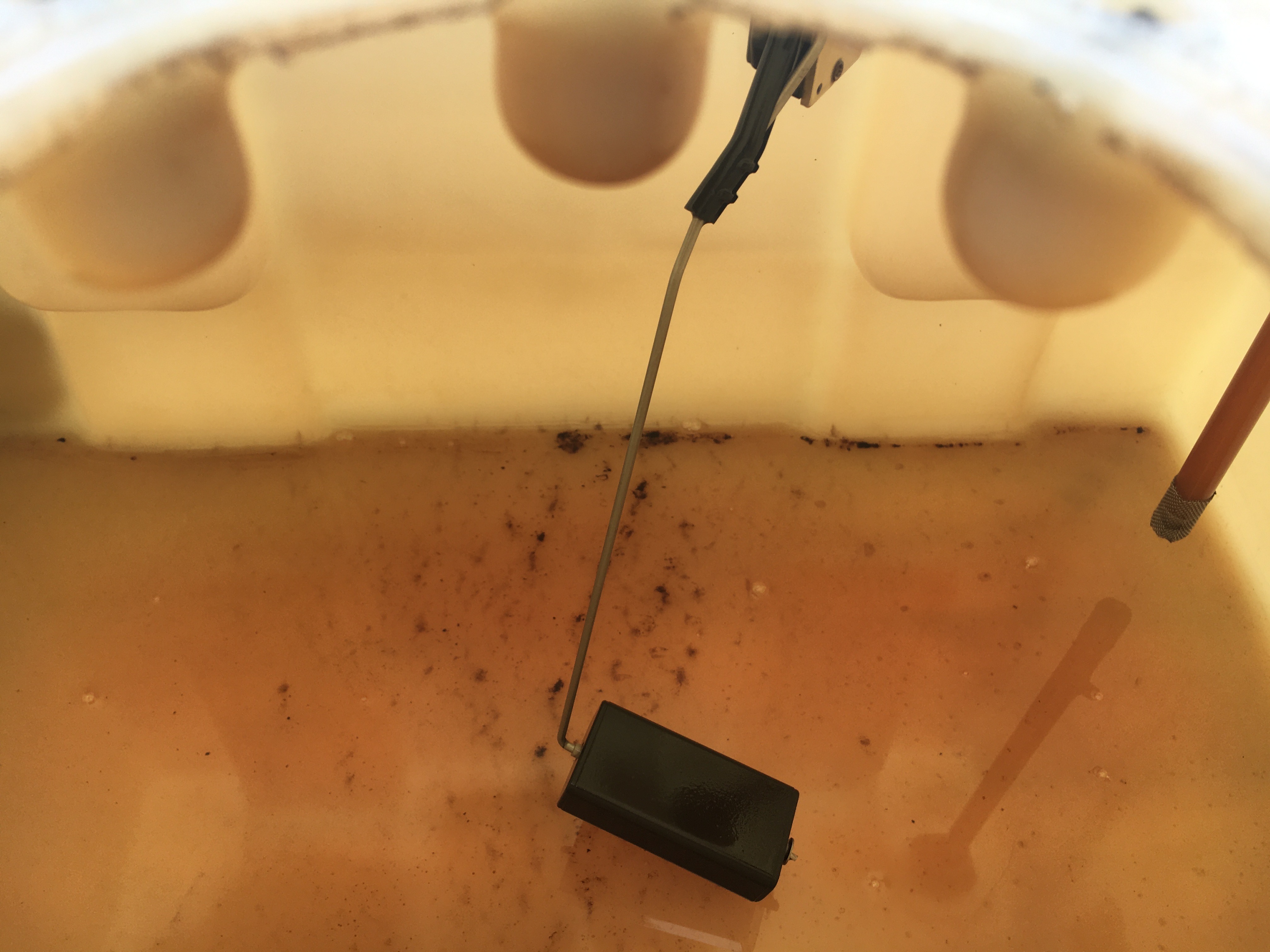

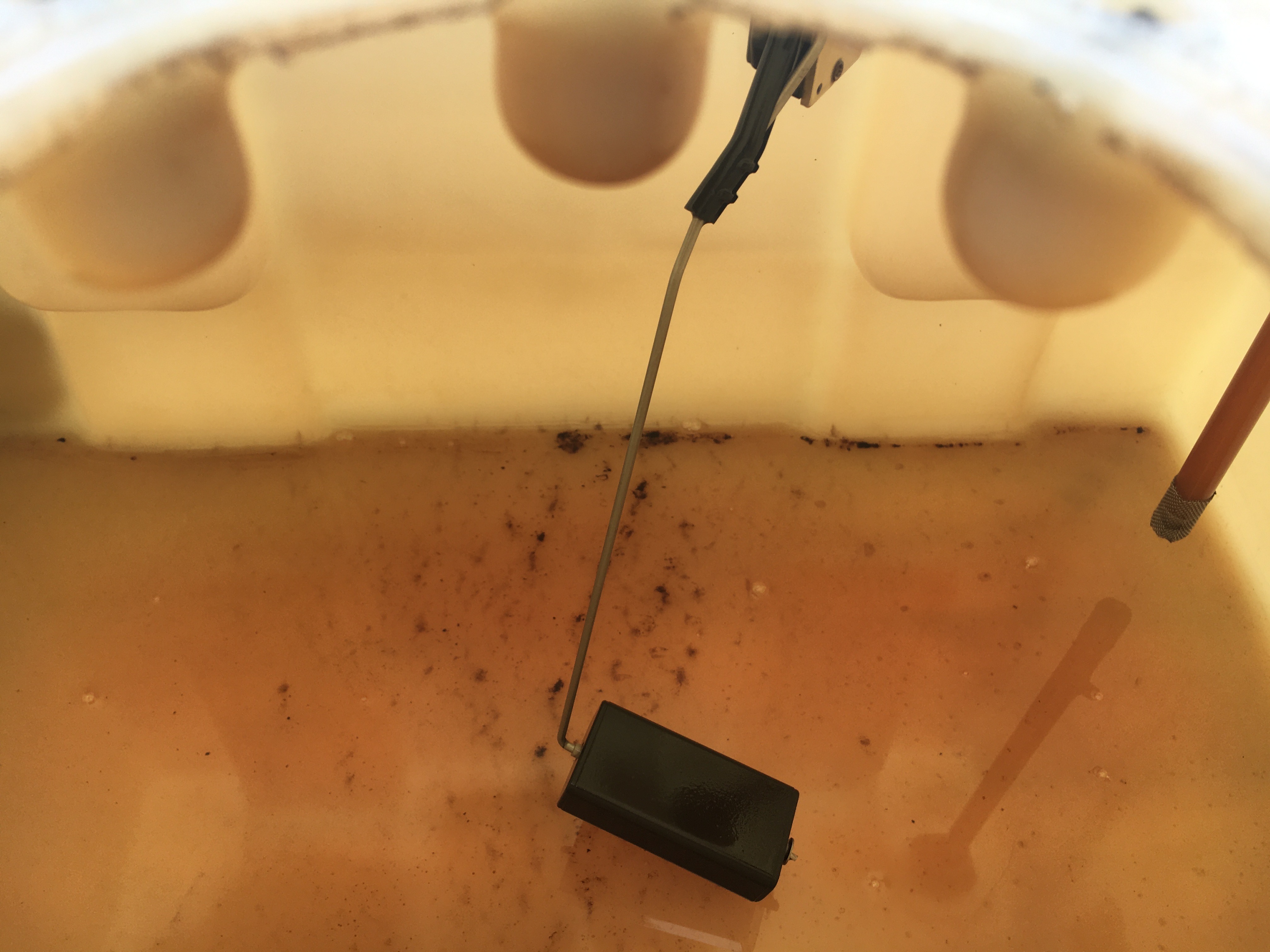

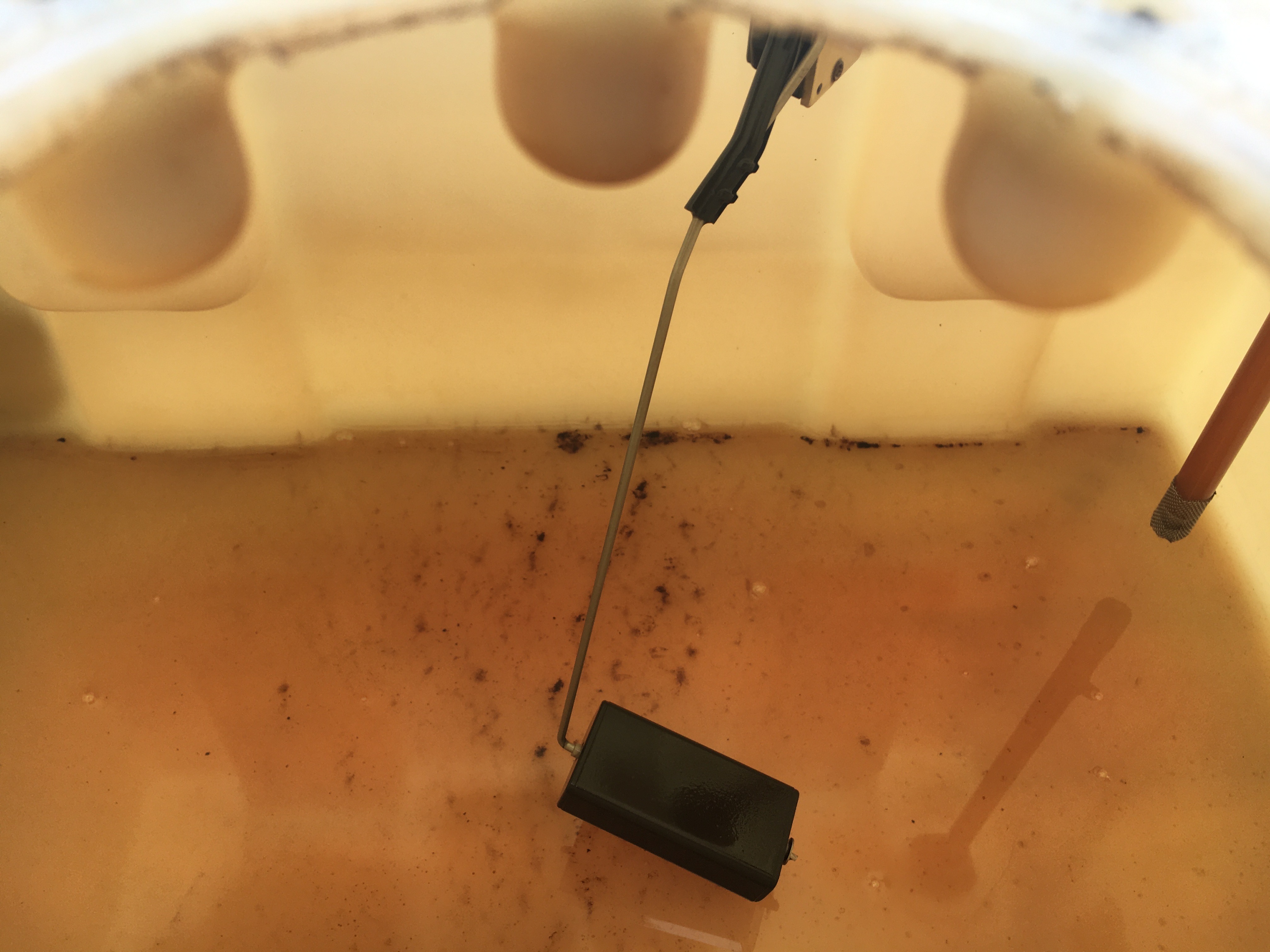

- Removed the inspection plate. Visible crud in the tank.

- Removed the tank from the lazarette. Removed the hose clamps from the fuel lines at the tank. Easier to removed the fuel fittings from the tank than to pull the fitting from the hose.

- Emptied about 2-1/2 gallons into milk containers.

- Wiped out the inside as best I could given the small size of the hole compared to my forearm.

- Dropped an oil absorbing cloth into the tank and wiped it out using a batten to move the cloth.

- Rinsed the inside of the tank with a bit of diesel.

- Greased the Groco valve for the while access was easy with the tank out. Wished that the shopvac was on the boat so that I could have vacuumed out the lazarette.

- Added Biobor JF Diesel

and Star Tron SEF Diesel

to tank. Have been remiss in adding these previously. Need to be rigorous.

- Reinstalled the tank.

- Walked to

Pier 4 Marina

. Bought four gallons of diesel. Added to tank.

- Replaced filter in Racor 110A.

- Ran engine. Somewhat rough. Not able to get above 2,200rpm. Stalled.

- Replaced on-engine fuel filter.

- Ran engine. Somewhat rough at start, settled over time. Able to run the engine about 3,000rpm.

- Washed cockpit.

Note: Fuel pickup is spaced off the bottom of the tank. Possible to run the tank down far enough that the engine will pick up a mix of air and fuel.

Note: Four gallons of fuel brings the level up to the indents for the hold-downs on the longer sides of the tank.

Note: Near end of run: 175* near injectors, 135* at aft end of heat exchanger, 91* at fore end of heat exchanger.