Removed the depthsounder. More difficult to do than I wished. The depthsounder had two fairing blocks: one external as an attempt to provide for smoother waterflow over the device, one internal to set the depthsounder vertical rather than perpendicular to the bigles. Tried to unscrew the ring inside the hull; no luck tabs broke off the ring and finally the ring itself broke. The depthsounder was bedded in a light brown rubbery adhesive, visible inside hole in hull on the interior fairing block. Had to break the fairing block out from under the depthsounder. That resulted in about half of the fairing flange of the depthsounder breaking off. Finally had to resort to a pipe wrench to unscrew the depthsounder from the hole and the adhesive.

Cleaned the area with acetone before any sanding.

Dished out an area about 5" in diameter around the hole in the hull, somewhat more than 1/4" through what appears to be three layers of roving, using a Ryobi angle grinder TC Williams lent me.

Filled the area with five layers of 1708 bi-axial cloth

wetted out fully with West System epoxy ( 105 epoxy resin

and 206 slow hardener

).

Used the Finned Roller

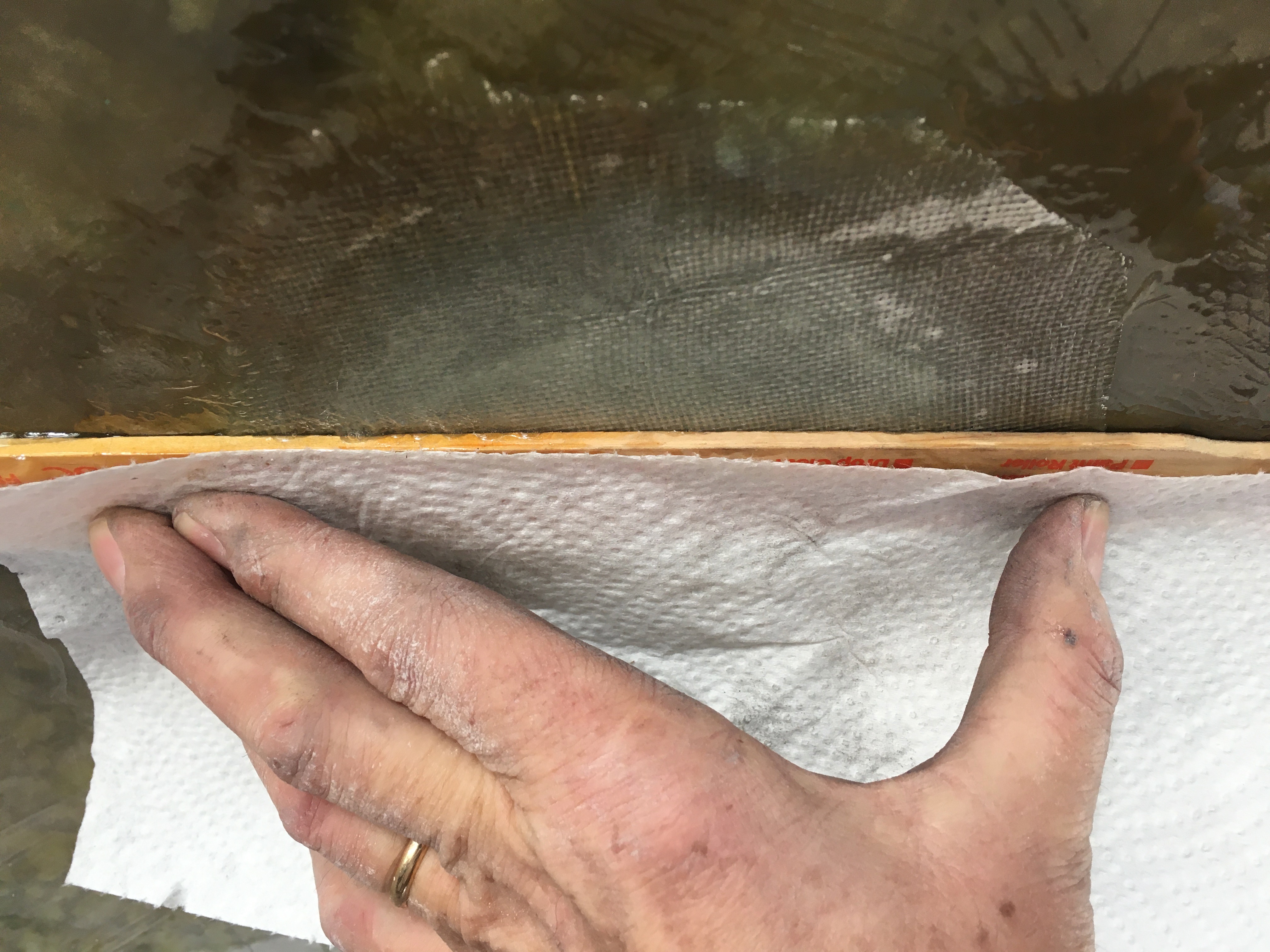

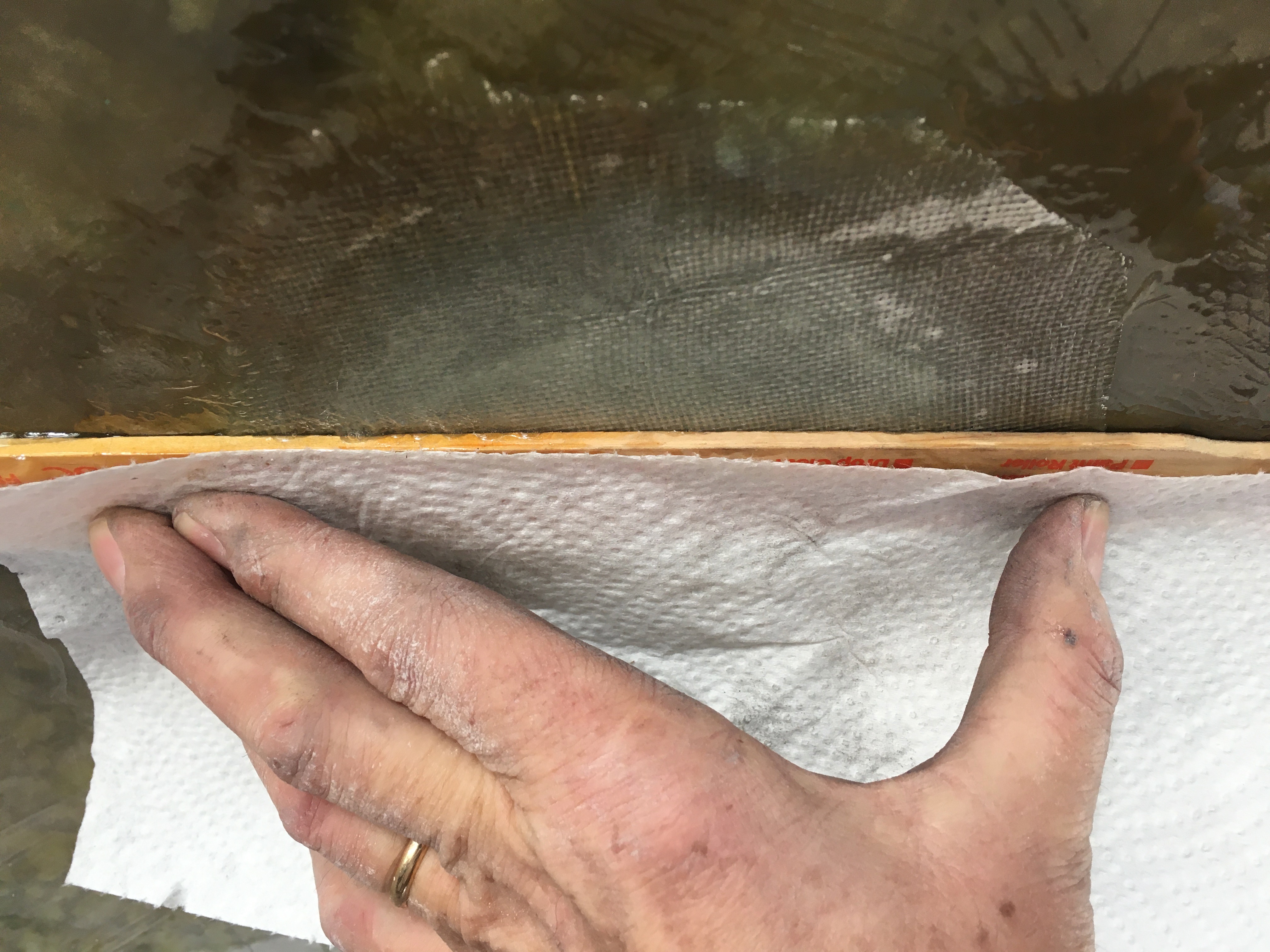

Applied a final finishing layer of 10oz fiberglass cloth.

Sanding to "get the blue out".

Sanded the starboard side from the galley sink discharge, aft of the depthsounder to the very stern of the boat.

Today completes the sanding of the hull but for the areas under the jackstands and the bottom of the keel.

before today's sanding.

before today's sanding.

after today's sanding, after rinsing away the sanding dust.

after today's sanding, after rinsing away the sanding dust.